Get in Touch

General

(508) 921-4600

Email Sales

Email Support

UEI Europe Office

+49 40 63698136

Email EU Sales

Visit this page for local offices and distributors.

Digital Twinning Tutorial Page

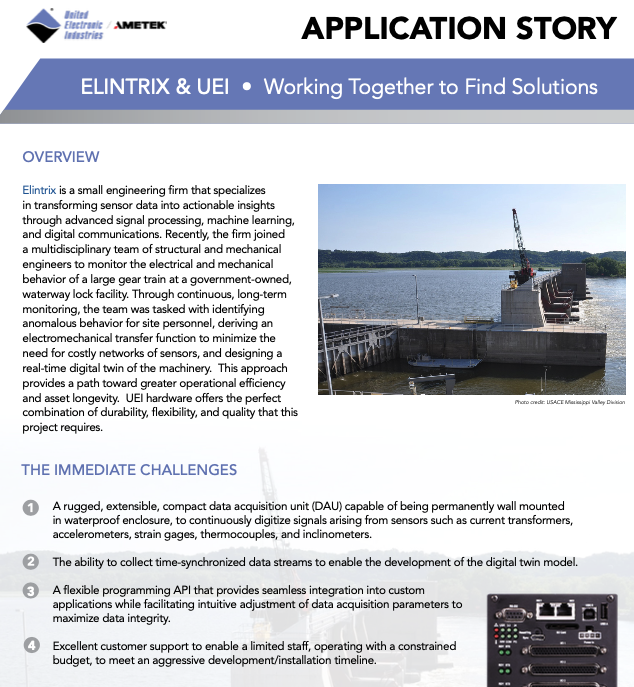

Digital twinning is a concept that involves creating a virtual representation or digital replica of a physical object, system, or process. It combines real-time data from the physical entity with a digital model, allowing engineers to simulate, analyze, and optimize its behavior.

Digital Twinning & Aerospace Testing

Digital twinning is an indispensable component of the aerospace test development process due to its ability to enhance efficiency, reduce costs, and mitigate risks. In the aerospace industry, where safety and reliability are paramount, by creating a virtual model that mirrors the behavior and characteristics of the actual asset, engineers can conduct extensive testing, identify potential issues, and optimize designs before physical prototypes are built. This iterative process helps to accelerate the development cycle and improve overall product quality.

Moreover, digital twinning facilitates the analysis and optimization of complex systems within aerospace vehicles. It allows engineers to monitor and assess the performance of various subsystems, such as propulsion, avionics, and control systems, both individually and in conjunction with one another. By integrating real-time data from sensors and other monitoring devices, digital twins can provide valuable insights into system behavior, enabling engineers to identify inefficiencies, troubleshoot problems, and make informed design decisions. This level of analysis is crucial in ensuring the safety and reliability of aerospace vehicles, as it helps engineers understand the interactions and dependencies among different components.

Furthermore, digital twinning plays a vital role in the ongoing maintenance and operation of aerospace assets. Once a physical asset is deployed, its digital twin continues to provide valuable support throughout its lifecycle. Real-time data from the physical asset can be compared to the digital twin's model, allowing engineers to detect anomalies, predict maintenance needs, and optimize operational efficiency. This proactive approach to maintenance helps minimize downtime, reduce costs, and improve overall asset performance.

Key Benefits to Aerospace Test Engineers

In the aerospace industry, digital twinning offers several benefits to engineers:

| Design and Simulation: Aerospace engineers can use digital twinning to design and simulate aircraft, spacecraft, or their components in a virtual environment. They can create accurate digital replicas of the physical assets and test various scenarios, configurations, and performance parameters. This allows them to optimize designs, identify potential issues, and make informed decisions before investing in physical prototypes. |

|---|---|

| Performance Monitoring and Predictive Maintenance: Digital twinning enables real-time monitoring of aircraft or spacecraft performance by collecting data from onboard sensors and systems. Aerospace engineers can compare the real-time data with the digital twin model to detect anomalies, predict failures, and schedule proactive maintenance. This approach helps improve safety, reduce downtime, and enhance the overall operational efficiency of aerospace systems. |

| Training and Simulation: Digital twinning can be utilized for training purposes. Aerospace engineers can create virtual environments that mimic real-world scenarios, enabling pilots, ground crew, and maintenance personnel to practice their skills in a realistic but risk-free setting. This enhances training effectiveness, reduces costs associated with physical simulations, and helps prepare personnel for various operational challenges. |

| Lifecycle Management and Optimization: Throughout the lifecycle of an aerospace system, digital twinning provides valuable insights for optimizing performance, reducing costs, and extending the operational lifespan. Engineers can continuously update the digital twin with real-time data, monitor performance trends, and identify areas for improvement. This facilitates data-driven decision-making, leading to better operational efficiency, maintenance planning, and asset management. |

| Collaboration and Communication: Digital twinning facilitates collaboration among aerospace engineers, allowing them to share and analyze data in real-time. Geographically dispersed teams can work together on the same virtual model, exchange insights, and make collective decisions. This collaboration streamlines communication, reduces errors, and accelerates the design, development, and maintenance processes. |

| Risk Mitigation: By leveraging digital twinning, aerospace engineers can mitigate risks associated with new technologies, system integration, or operational changes. They can simulate and validate new concepts, assess potential risks, and identify solutions before implementing them in the physical world. This proactive approach reduces the likelihood of unforeseen issues, improves safety, and minimizes costly redesigns or rework. |

Overall, digital twinning empowers aerospace engineers to design, analyze, optimize, and maintain aerospace systems more effectively. It enhances decision-making, improves operational efficiency, reduces costs, and mitigates risks throughout the lifecycle of aircraft, spacecraft, and their components.

Key components of a Digital Twinning system

A digital twinning system typically consists of the following key components:

| Physical Asset or System: The digital twinning process starts with the physical asset or system that is being replicated in the digital world. This can be an aircraft, spacecraft, manufacturing equipment, infrastructure, or any other object of interest. The physical asset serves as the basis for capturing real-time data and understanding its behavior. |

|---|---|

| Sensors and Data Acquisition: Sensors are deployed on the physical asset to collect real-time data about its various parameters such as temperature, pressure, vibration, position, speed, and more. These sensors capture data at regular intervals and transmit it to the digital twin system. The data acquisition process is crucial for maintaining an accurate representation of the physical asset in the digital twin. |

| Communication Infrastructure: A robust communication infrastructure is required to transmit the data from the sensors to the digital twinning system. This infrastructure can include wired or wireless networks, IoT (Internet of Things) protocols, data buses, or any other means of transferring the sensor data reliably and securely. |

| Data Processing and Analytics: Once the sensor data is collected, it undergoes processing and analysis to extract meaningful insights. This involves techniques such as data cleansing, aggregation, filtering, and statistical analysis. Advanced analytics techniques, including machine learning and artificial intelligence algorithms, can be applied to detect patterns, anomalies, and predictive behaviors. |

| Digital Twin Model: The digital twin model is a virtual representation of the physical asset or system. It encompasses the geometry, structure, behavior, and other characteristics of the physical entity. The model can range from simple 3D geometries to complex simulations that replicate the dynamics and interactions of various components. |

| Integration and Interoperability: To create an accurate digital twin, data from various sources and systems need to be integrated. This involves integrating sensor data, historical data, CAD (Computer-Aided Design) models, simulation models, and other relevant data sources. Interoperability standards and protocols are necessary to ensure seamless integration and data exchange between different components of the digital twinning system. |

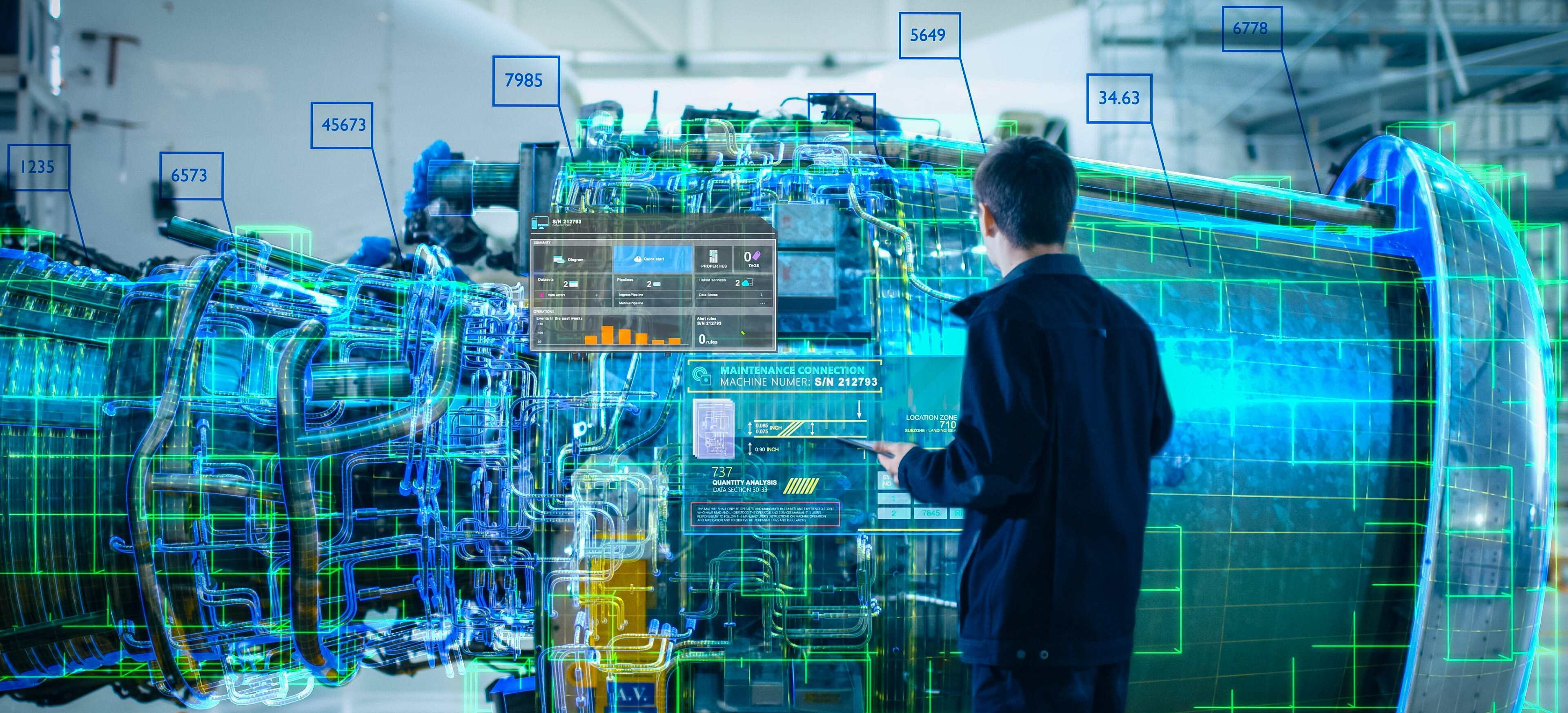

| Visualization and User Interface: The digital twin system should provide a user-friendly interface for engineers, operators, and stakeholders to interact with the virtual representation. Visualization tools, dashboards, and 3D rendering technologies can be employed to display the digital twin model and present real-time data in a comprehensible manner. |

| Feedback Loop and Control: A key aspect of digital twinning is the ability to close the feedback loop between the physical asset and its digital twin. The insights and predictions generated from the digital twin can be used to make informed decisions, optimize operations, and control the behavior of the physical asset. Control mechanisms, automation systems, and simulation-based control algorithms enable this feedback loop. |

These components work together to create a digital twin system that bridges the physical and digital worlds, enabling engineers to monitor, analyze, simulate, and optimize the behavior of complex systems in real-time.

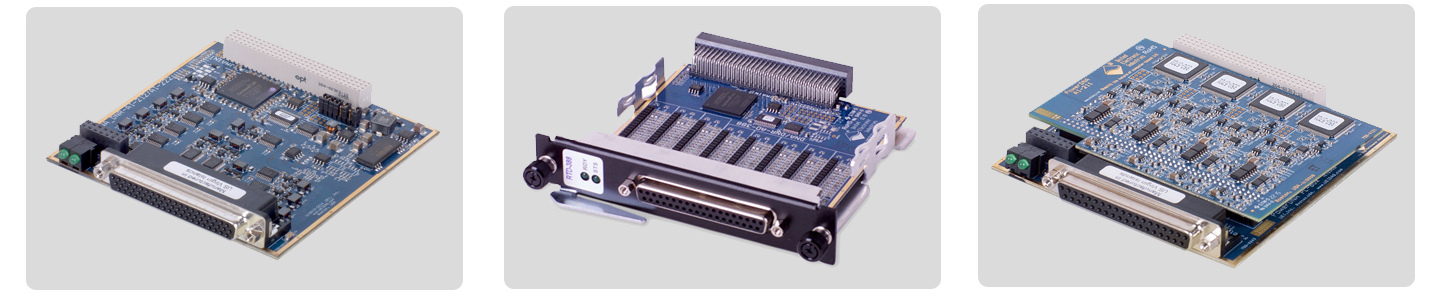

UEI's Digital Twinning Solutions

|

|

|

|

|

Read about UEI Digital Twinning in Unmanned Systems Technology